Kuongororwa kwezvikonzero zve gypsum dehydration matambudziko

1 Boiler mafuta kudyisa uye yakagadzikana kupisa

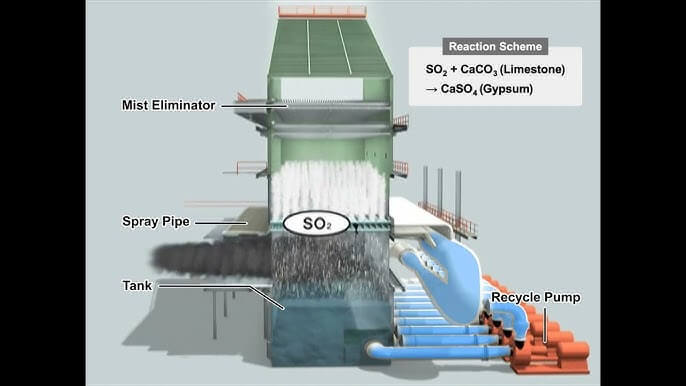

Maboiler emagetsi emagetsi emarasha anofanirwa kushandisa huwandu hukuru hwemafuta ekubatsira kupisa panguva yekutanga, kudzima, kudzika-mutoro wakatsiga kupisa uye yakadzika peak mutemo nekuda kwekugadzira uye kupisa marasha. Nekuda kwekushanda kusina kugadzikana uye kusakwana kwekupisa kwebhailer, huwandu hwakati wandei hwemafuta asina kupiswa kana musanganiswa wehupfu hwemafuta huchapinda muabsorber slurry ine flue gasi. Pasi pekuvhiringidza kwakasimba mumudziyo, zviri nyore kwazvo kuumba foam yakanaka uye kuunganidza pamusoro pe slurry. Uku ndiko kuumbwa kwekuongorora kwefuro pamusoro peiyo absorber slurry yemagetsi emagetsi.

Ipo mafuta ari kuungana pamusoro pe slurry, chikamu chayo chinokurumidza kuparadzirwa mumhepo inonyura pasi pekubatana kwekukurudzira nekupfapfaidza, uye firimu remafuta rakaonda rinoumbwa pamusoro pe limestone, calcium sulfite uye zvimwe zvimedu mu slurry, iyo inoputira limestone nezvimwe zvimedu, zvichitadzisa kunyungudika kweimestone, kukanganisa kunyungudika kweimestone. desulfurization kunyatsoita uye kuumbwa kwegypsum. Iyo mafuta-ine absorption tower slurry inopinda mugypsum dehydration system kuburikidza nepombi yekuburitsa gypsum. Nekuda kwekuvapo kwemafuta uye zvisina kukwana oxidized sulfurous acid zvigadzirwa, zviri nyore kuita kuti vacuum bhandi rekufambisa sefa jira gap kuvharika, izvo zvinotungamira kunetsa mukupererwa kwegypsum.

2.Smoke Concentration paInlet

Iyo wet desulfurization absorption tower ine imwe synergistic guruva yekubvisa maitiro, uye guruva rayo rekubvisa guruva rinogona kusvika 70%. Chigadzirwa chemagetsi chakagadzirirwa kuve neguruva rekuti 20mg/m3 padust collector outlet (desulfurization inlet). Kuti uchengetedze simba uye uderedze kushandiswa kwemagetsi ezvirimwa, iyo chaiyo guruva yekuisa panzvimbo yekuunganidza guruva inodzorwa inenge 30mg/m3. Guruva rakawandisa rinopinda mushongwe yekunyura uye rinobviswa neiyo synergistic guruva rekubvisa maitiro eiyo desulfurization system. Zvizhinji zvehuruva zvimedu zvinopinda mushongwe yekunyura mushure mekucheneswa kweguruva kwe electrostatic isingasviki 10μm, kana kunyange isingasviki 2.5μm, inova idiki pane saizi yegypsum slurry. Mushure mekunge guruva rapinda muvhavha bhandi rekutakura negypsum slurry, rinovharawo jira resefa, zvichiita kuti mhepo yakashata iparadze jira resefa uye kuoma kwegypsum dehydration.

2. Kufurira kwegypsum slurry quality

1 Slurry density

Saizi ye slurry density inoratidza kuwanda kweiyo slurry mushongwe yekunyura. Kana iyo density yakanyanya kudiki, zvinoreva kuti iyo CaSO4 yemukati mune slurry yakaderera uye iyo CaCO3 yemukati yakakwira, izvo zvinokonzeresa kutambisa kweCaCO3. Panguva imwecheteyo, nekuda kwediki CaCO3 particles, zviri nyore kukonzera gypsum dehydration matambudziko; kana slurry density yakakura kwazvo, zvinoreva kuti CaSO4 yemukati mune slurry yakakwirira. Yakakwira CaSO4 inotadzisa kunyungudika kweCaCO3 uye inhibisa kubatwa kweSO2. CaCO3 inopinda muvacuum dehydration system negypsum slurry uye inokanganisawo kupera kwemvura kwegypsum. Kuti upe kutamba kwakazara kune zvakanakira iyo kaviri-tower-yekutenderera system ye wet flue gasi desulfurization, iyo pH kukosha kweiyo nhanho yekutanga shongwe inofanirwa kudzorwa mukati mehupamhi hwe5.0±0.2, uye slurry density inofanira kudzorwa mukati meiyo 1100±20kg/m3. Mukushanda chaiko, slurry density yeshongwe yekutanga-yechirimwa inenge 1200kg / m3, uye kunyange inosvika 1300kg / m3 panguva dzakakwirira, iyo inogara ichidzorwa pamwero wakakwirira.

2. Dhigirii yekumanikidzwa oxidation ye slurry

Kumanikidzirwa oxidation ye slurry ndeyekuunza mweya wakakwana muslurry kuita kuti oxidation ye calcium sulfite ku calcium sulfate reaction iite kunge yakakwana, uye iyo oxidation rate yakakwira kupfuura 95%, kuve nechokwadi kuti kune akakwana egypsum marudzi muslurry yekukura kwekristaro. Kana iyo oxidation isina kukwana, makristasi akasanganiswa ecalcium sulfite uye calcium sulfate anogadzirwa, zvichikonzera kuwedzera. Iyo dhigirii yekumanikidzwa oxidation ye slurry inoenderana nezvinhu zvakaita sehuwandu hwemhepo oxidation, nguva yekugara yeslurry, uye inosimudzira mhedzisiro ye slurry. Mhepo isina kukwana oxidation, nguva shoma yekugara yeslurry, kusaenzana kugovera kweslurry, uye kusaita zvakanaka kukonzeresa zvese zvinokonzeresa kuti CaSO3 · 1/2H2O zvirimo mushongwe ive yakawandisa. Zvinogona kuonekwa kuti nekuda kwekusakwana kwe oxidation yemunharaunda, CaSO3 · 1 / 2H2O zvinyorwa mu slurry zvakanyanya kukwirira, zvichiita kuti kuomerwa kwegypsum dehydration uye nehuwandu hwemvura.

3. Hutsvina huri mutsvina. Izvi zvinosvibisa zvinogadzira ion dzisina kuchena mune slurry, zvichikanganisa chimiro chelatiti chegypsum. Simbi dzinorema dzinoramba dzichinyungudutswa muutsi dzinotadzisa kuita kweCa2+ uye HSO3-. Kana zvinyorwa zveF- neAl3 + mu slurry zvakakwirira, fluorine-aluminium yakaoma AlFn ichagadzirwa, inovhara pamusoro pemarara emarara, zvichiita kuti slurry poisoning, kuderedza desulfurization kushanda zvakanaka, uye zvidimbu zveraimestone zvakasanganiswa zvisina kukwana zvakagadziriswa gypsum crystals, zvichiita kuti zvive zvakaoma kubvisa gypsum. Cl- in slurry inowanzobva kuHCl muflue gas uye kugadzirisa mvura. Iyo Cl- yemukati mumvura inoshandiswa idiki, saka Cl- in slurry inowanzobva ku flue gas. Kana paine huwandu hukuru hweCl- in slurry, Cl- ichaputirwa nemakristasi uye yakabatanidzwa nehuwandu hweCa2 + mu slurry kuti iite CaCl2 yakagadzikana, ichisiya imwe mvura mumakristasi. Panguva imwecheteyo, imwe nhamba yeCaCl2 mu slurry icharamba iri pakati pemakristasi egypsum, ichivhara nzira yemvura yakasununguka pakati pemakristasi, zvichiita kuti mvura yegypsum iwedzere.

3. Kufurira kwemamiriro ekushanda kwemidziyo

1. Gypsum dehydration system Gypsum slurry inopomba kune gypsum cyclone kuitira kupera simba kwekutanga kuburikidza nepombi yegypsum discharge. Kana iyo yepasi inoyerera slurry yakanamirwa kune yakasimba yemukati inosvika 50%, inoyerera ichienda kune vacuum bhandi conveyor yekubvisa kwechipiri mvura. Izvo zvinhu zvikuru zvinokanganisa kupatsanurwa kweiyo gypsum cyclone ndiyo cyclone inlet pressure uye saizi yejecha rinogadzika nozzle. Kana iyo cyclone inlet pressure yakanyanya kuderera, iyo yakasimba-yemvura yekuparadzanisa mhedzisiro ichave yakashata, iyo yepasi inoyerera slurry ichange iine zvishoma yakasimba yemukati, izvo zvinokanganisa dehydration mhedzisiro yegypsum uye kuwedzera mvura yemukati; kana dutu remhepo rinopinda mukati rakanyanyisa, kupatsanurwa kunenge kuri nani, asi kunokanganisa kurongeka kwechamupupuri uye kukonzeresa kupfeka kwakanyanya pamidziyo. Kana saizi yejecha inogadzika muromo yakakurisa, ichaitawo kuti pasi inoyerera slurry ive isina kusimba zvemukati uye zvidiki zvimedu, izvo zvinokanganisa kupera kwemvura kweiyo vacuum bhandi conveyor.

Yakanyanya kukwira kana yakaderera vacuum ichakanganisa iyo gypsum dehydration effect. Kana iyo vacuum yakanyanya kuderera, kukwanisa kubvisa unyoro kubva kugypsum kuchaderedzwa, uye gypsum dehydration effect ichava yakaipa; kana vacuum yakawandisa, maburi ari mumucheka wesefa anogona kuvharika kana bhandi rinogona kutsauka, izvo zvinozotungamira kune yakaipisisa gypsum dehydration effect. Pasi pemamiriro akafanana ekushanda, zviri nani kupenya kwemhepo kwejira resefa, zviri nani gypsum dehydration effect; kana mhepo inopera yejira resefa isina kunaka uye chiteshi chesefa chakavharwa, iyo gypsum dehydration effect ichave yakaipisisa. Iyo sefa keke ukobvu zvakare ine yakakosha mhedzisiro pagypsum dehydration. Kana bhanhire rekutakura rinomhanya richiderera, kukora kwekeke yesefa kunowedzera, uye kukwanisa kwepombi yevacuum kubvisa chikamu chepamusoro chekeke chesefa kunopera simba, zvichiita kuti kuwedzera kwegypsum hunyoro hwemukati; kana bhanhire rekutakura rinomhanya richiwedzera, iyo sefa keke ukobvu inoderera, izvo zviri nyore kukonzera yemuno sefa keke kuvuza, kuparadza vacuum, uye zvakare kukonzera kuwedzera kweiyo gypsum mwando.

2. Kushanda kusina kujairika kwe desulfurization wastewater treatment system kana kuti uwandu hudiki hwekuchenesa mvura yetsvina huchakanganisa kubuda kwakajairika kwe desulfurization wastewater. Pasi pekushanda kwenguva refu, tsvina yakadai seutsi uye guruva icharamba ichipinda muslurry, uye simbi inorema, Cl-, F-, Al-, etc. mu slurry icharamba ichipfumisa, zvichiita kuti kuenderera mberi kuparara kwe slurry quality, kunokanganisa kufambira mberi kwemaitiro e desulfurization, gypsum formation uye kupera mvura. Tichitora Cl- in slurry semuenzaniso, iyo Cl- yemukati mune slurry yeyekutanga-level absorption tower yemagetsi plant yakakwira kusvika 22000mg/L, uye Cl- content mugypsum inosvika 0.37%. Kana iyo Cl- yemukati mune slurry inenge 4300mg/L, iyo dehydration mhedzisiro yegypsum iri nani. Sezvo iyo chloride ion yemukati inowedzera, iyo dehydration mhedzisiro yegypsum inoderera zvishoma nezvishoma.

Kudzora matanho

1. Simbisa kugadzirisa kwekupisa kwekushanda kwebhailer, kuderedza kukanganiswa kwejekiseni remafuta uye kupisa kwakadzikama pane desulfurization system panguva yekutanga-up uye kudzima nhanho yebhailer kana yakaderera-mutoro kushanda, kudzora huwandu hwemapombi ekutenderera anoiswa mukushanda, uye kuderedza kusvibiswa kwemafuta asina kupiswa poda musanganiswa kune slurry.

2. Tichifunga nezvekushanda kwakasimba kwenguva refu uye hupfumi hwese hwe desulfurization system, kusimbisa kugadziriswa kwekushanda kwemuunganidzi weguruva, kutora kushandiswa kwepamusoro kweparameter, uye kudzora guruva rekutsvaga padust collector outlet (desulfurization inlet) mukati mekugadzirisa kukosha.

3. Chaiyo-nguva yekutarisa slurry density (slurry density mita), oxidation air volume, absorption tower fluid level (radar level mita), slurry inosimudzira mudziyo, nezvimwewo kuve nechokwadi chekuti desulfurization reaction inoitwa pasi pemamiriro akajairwa.

4. Simbisa kuchengetedza uye kugadzirisa gypsum cyclone uye vacuum bhandi conveyor, chengetedza inlet pressure yegypsum cyclone uye dhigirii yevacuum yebhanhire rinotakura mukati mehutano hunonzwisisika, uye gara uchitarisa dutu remhepo, jecha rinogadzirisa muromo uye jira resefa kuti uone kuti midziyo inoshanda mumamiriro ezvinhu akanaka.

5. Ita shuwa kushanda kwakajairika kweiyo desulfurization wastewater treatment system, inogara ichibudisa desulfurization wastewater, uye kuderedza kusvibiswa kwemukati mu absorption tower slurry.

Mhedziso

Kuoma kwegypsum dehydration idambudziko rakajairika mune wet desulfurization michina. Pane zvakawanda zvinofurira zvinhu, zvinoda kuongororwa kwakadzama uye kugadzirisa kubva kune akawanda maficha senge ekunze midhiya, maitiro ekuita uye mamiriro ekushandisa kwemidziyo. Chete nekunzwisisa zvakadzama maitiro ekuita desulfurization uye maitiro ekushandisa kwemidziyo uye kudzora zvine hungwaru iwo makuru ekushandisa ma parameter eiyo system anogona kuomeserwa mhedzisiro ye desulfurized gypsum kuvimbiswa.

Nguva yekutumira: Feb-06-2025