Polymer melt viscosity kuyerwa inosarudza extrusion uye kuumba maitiro. Real-time viscosity monitoring inonyanya kukosha pane tembiricha uye kudzvanywa kwekutarisa.

Overviewof ExtrusinMoldingProcess

Extrusion molding inzira inobudirira yekugadzira mumaindasitiri akawanda ekugadzira maprofiles anoenderera semapombi, mafirimu, mashiti, etc. Inogonesa kugadzirwa kweakaomesesa-sectional maumbirwo mumhando inowirirana uku ichivimbisa kukurumidza kwekugadzira uye kugona kwezvinhu. Kufambira mberi kuri pachena senge process otomatiki, chaiyo-nguva yekutarisa uye yekudzokorodza maitiro ekutarisa zvakavandudza humbowo uye nekuderedza kukanganiswa kwezvakatipoteredza kuburikidza nekuderedza marara.

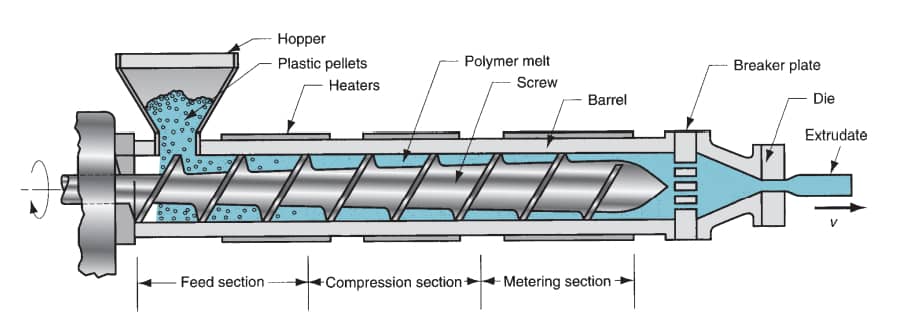

Rough Idea yeExtrusionMachine

Muchina weextrusion une zvikamu zvinotevera: hopper, feeding screw, zvinhu zvekudziya uye pombi yegiya. Material anodyiswa mumushini pane hopper. Iyo inoramba ichitenderera yekudyisa sikuru, inotyairwa nemota uye giya bhokisi, inofambisa zvinhu pamwe nedhiramu uye kuburikidza nefa. Zvinhu zvinodziya pamwe chete nedhiramu zvinochengetedza tembiricha inodzorwa kupfava uye kunyungudutsa iyo polymer zvinhu. Pashure pokunge yabuda mudhishi, chinhu chakanyungudutswa chinopinda muforoma ine gomba rimwe kana kupfuura, uko chinotonhorerwa ndokuoma kuva chimiro chaunoda. Mune mamwe masisitimu, pombi yegiya inoiswa pakati pembiru uye inofa kuti ive nechokwadi chisingachinjiki kumanikidza mune zvinobuda zvinhu.

Key Viscosity Kuyera Mapoinzi pane Extrusion Machine

Hopper Exit / Feed Zone: Inoyera yekutanga kunyunguduka viscosity sezvo iyo polymer inotanga kupfava.

Melting Zone (Mid-Barrel): Inobata shanduko kuenda kune yakanyungudutswa zvizere.

Metering Zone(Pamberi peGear Pombi kana Kufa): Inoyera polymer inonyungudutsa viscosity kuyerwa pasi pekushanda kweshear rates.

Die Entrance: Inopa chaiyo-nguva yakanyunguduka viscosity data panzvimbo yeextrusion.

Kunzwisisa Polymer Melt uye Viscosity

Chii chinonzi polymer melt?

Iyo polymer inopisa kune yakanyungudutswa nyika, ichiratidza kuyerera zvivakwa zvinobvumira kuumbwa kuburikidza neextrusion kana kuumbwa. Thekunyungudutsa viscosity yemapolymers-kuramba kuyerera-kunoenderana nehuremu hwema molecular, tembiricha, shear rate, uye zvinowedzera, zvichipesvedzera simba uye kupera kwechigadzirwa chekupedzisira. Mupolymer extrusion process, uko polymer yakanyungudutswa inoburitswa kuburikidza nekufa, uye mukuumbwa kwejekiseni, uko inozadza mold pasi pekumanikidzwa, kuchengetedza zvakakwana.nyungudutsa viscositykwakakosha. Traditionalpolymer melt viscosity kuyerwanzira, dzakadai se-off-line capillary rheometry, inowanzononoka nekuda kwekunonoka, zvichiita kuti kuchinja kuinlineviscometer ye polymerskune chaiyo-nguva ruzivo.

Matambudziko muPolymer Extrusion uye Maitiro Kudzora

Thepolymer extrusion processuye kuumba jekiseni kunotarisana nezvipingamupinyi zvakakosha mukuchengetedza kuenderananyungudutsa viscosity. Kusiyana nekuda kwekupisa kwemagetsi uye kushanduka kweshear mitengo kunogona kutungamirira kune kusaenzanakunyungudutsa viscosity yemapolymers, zvichikonzera kukanganisa senge kusarongeka kwepamusoro kana voids mumaprofiles akawedzerwa. Mitsetse mikuru yeextrusion inonetsana neyunifomupolymer melt viscosity kuyerwamhiri kwekuyerera, kuchengetedza kutevedza mukutonga kwemaitiro. Mukugadzira jekiseni repamusoro-soro, zvigadziriso zvemanyorero zvinotadza kufambirana nenguva yekutenderera, zvichiisa njodzi yehondo kana kusazadza kusina kukwana. Matambudziko aya anosimbisa kudiwa kwepamusoropolymer viscometermasisitimu, akadai seotomatiki polymer viscometer, kupa data chaiyo-nguva uye kukunda zvisingakwanisi nzira dzechinyakare.

Sei Melt Viscosity Monitoring Matters

Melt viscosity kuyerwa kwakakosha mu polymer extrusion process uye jekiseni kuumba nekuda kwezvikonzero zvakati. Mu extrusion, inowirirana melt viscosity inova nechokwadi chekuti yunifomu inofa izere uye inodzivirira kuremara senge kusarongeka kwepamusoro kana kufa kuzvimba. Mukugadzira jekiseni, inokanganisa kuzadza mold, chikamu chemhando, uye nguva yekutenderera, uko misiyano inogona kutungamira kune warpage kana kusakwana kuzadzwa. Real-time yekutarisa inobvumira vashandisi kugadzirisa tembiricha, kudzvanywa, kana kuumbwa kwezvinhu panhunzi, kugadzirisa mashandisiro esimba uye kuderedza tsvina - zvakakosha zvinonetsa sezvo kabhoni mitemo inoomesa muna 2025.

Iyo yakaoma yepolymer melt viscosity kuyerwa kunobva kune isiri-Newtonian hunhu hwepolymer inonyungudika, uko viscosity inosiyana neshear rate uye nhoroondo yekupisa. Masisitimu einline polymer-melt viscometer masisitimu anogadzirisa izvi nekupa inoenderera data, ichigonesa kudzora maitiro ayo nzira dzekunze dzisingaenderane.

Lonnmeter's Unyanzvi muMelt Viscosity Monitoring

Neanopfuura makore gumi echiitiko,Lonnmeter, mutungamiripolymer viscometer mutengesi, yakazvisimbisa imene sapiyona muviscosity monitoring. Hunyanzvi hwavo hunotambanudzira kudzvanya-kudzvanya, kukwirisa-kupisa mitsetse uye zvivakwa zvekuumba jekiseni, kugadzirisa zvinodikanwa zvemapolymer akasiyana senge polyethylene, polypropylene, uye PET.

Product Solutions

Lonnmeter inopa yekucheka-kumuchetopolymer yakanyungudutsa viscometermhinduro dzakagadzirirwanyungudutsa viscosity monitoring. TheInline Viscometeryakagadzirirwa perpendicular kana parallel kuiswa mumashini eextrusion, kuyeranyungudutsa viscositykusvika ku100,000 cP·s uye tembiricha inosvika 300°C, isingabatsirwe nekusiyana kwekuyerera.

Kugadziridza chiratidzo chezvipo zveLonnmeter, iine sarudzo dzekubatanidza kana tambo dzekubatanidza uye kuburitsa data kuburikidza ne4-20mA kana RS485, ichibatanidza isina musono neatomatiki masisitimu. Mu extrusion, iyo perpendicular setup inovimbisa kushoma kuyerera kukanganiswa.

Mabhenefiti eLonnmeter's Melt Viscosity Solutions

Hunhu Hwaro:Nguva chaiyopolymer melt viscosity kuyerwainova nechokwadi chekuremara-isina extrudates uye zvikamu zvakaumbwa.

Kubudirira Kwemari:Kuderedzwa kwemarara uye kugadzirisa mari yekushanda yakaderera.

Kuchengetedza Simba:Kugadziridza chaiko kunogonesa kushandiswa kwesimba.

Process Flexibility:Kuenderana nemapolymer akasiyana-siyana anotsigira zvakasiyana siyana zvekugadzira zvinodiwa.

Kuchengetedzwa Kwakawedzerwa:Kuonekwa kwekutanga kwe viscosity anomalies kunodzivirira kunetsa kwemidziyo.

FAQs

Sei kunyunguduka viscosity yakakosha kupfuura tembiricha kana kumanikidza?

Melt viscosity inokanganisa kunyungudika kuyerera, kufa kuzadzwa, uye kuenderana kwechigadzirwa, kazhinji kudarika simba rekushisa kana kudzvanywa. Yakakodzera polymer melt viscosity kuyerwa kunodzivirira kuremara senge warpage kana kufa kuzvimba, zvichiita kuti ive yakakosha pakudzora maitiro.

Ko Lonnmeter inovimbisa sei kubatanidzwa kwedata?

Iyo otomatiki polymer viscometer inosanganisa kuburikidza ne4-20mA kana RS485 mapuroteni, ichipa chaiyo-nguva data kudzora masisitimu. Yayo onboard munyori wenhoroondo, inowanikwa kuburikidza nesoftware, inopa nhoroondo yekuziva, kupfuura echinyakare viscometer polymer zvipimo.

Ndezvipi zvinhu zvinokonzeresa kunyungudika viscosity yemapolymers?

Iyo yakanyunguduka viscosity yemapolymers inokanganiswa nehuremu hwemamorekuru, tembiricha, shear rate, uye kuvapo kwezvinowedzera kana mafirita. Yepamusoro mamorekuru huremu uye tembiricha yakaderera inowanzo wedzera viscosity, inokanganisa iyo polymer extrusion process.

Melt viscosity yekutarisa ibwe repakona yepolymer extrusion process uye jekiseni kuumba, kuve nechokwadi chemhando uye kushanda nesimba. Iine Lonnmeter's yakaratidza hunyanzvi uye yepamberi viscometer yemapolymer, vagadziri vanogona kukunda matambudziko mukugadzirisa maitiro uye kukwirisa kugadzirwa. Kumbira quote nhasi kubva kune uyu akavimbika wepolymer viscometer mutengesi!

Nguva yekutumira: Jul-31-2025