Bulk Density yePepa Pulp

Lonnmeteryakagadzira nekugadzira michina yekuyeresa yekuwanda kwehuwandu hwepepa pulp, doro dema nedoro regirinhi. Zvinogoneka kuona kuwanda kwezvinhu zvakanyungudutswa kana zvisina kunyungudika kuburikidza nemeta imwechete density yakaiswa mumutsara. Isu tinopa mhinduro kune density uye kuyera kuyerwa kwezvishandiso sezvinwiwa zvitema, girinhi zvinwiwa zvemapepa pulps. Uye zvakare, pulp density metres inokwanisa kuyera kuwanda kweimu dope kana pasina hukuru-hukuru zvidimbu uye mitoro yemabhuru.

Sei Uchida Kuramba Uchiyera Density Measurement?

Uneven pulpmukugadzira mapepa kunounza njodzi dzinogona kuitika pamhando isina kugadzikana yezvigadzirwa zvekupedzisira uye kuwedzera mutengo mukugadzira mapepa. Pepa pulp rine kumiswa kwefiber mumvura zvakaenzana. Iyo isiri-uniformity mu density inopesvedzera iyo yese bepa maitiro.

Variable consistencyye pulp inosiya viscosity yayo ichichinja pamwe nechiyero chekugera, ichiwedzera imwe layer yekuoma kune inoenderera mberi density kuyerwa. Zvisizvo zvinokura zvakanyanya nokuda kwechikonzero chemhepo yakavharirwa, iyo inofananidzira semapupu mumusanganiswa, zvichikonzera kuverenga kwenhema uye kuderedza kurongeka.

Nzira dzechinyakare dzinoshandiswa pakuyera density dzinowanzo sangana muchokwadi kana paine shanduko yemashandiro. Semuenzaniso, gravimetric nzira hadzina kukodzera kuenderera mberi nekutarisa nekuda kwekushanda nesimbauyekubatwa nemhosho dzesampling.

Mapoinzi ekuyera muPepa Pulp process

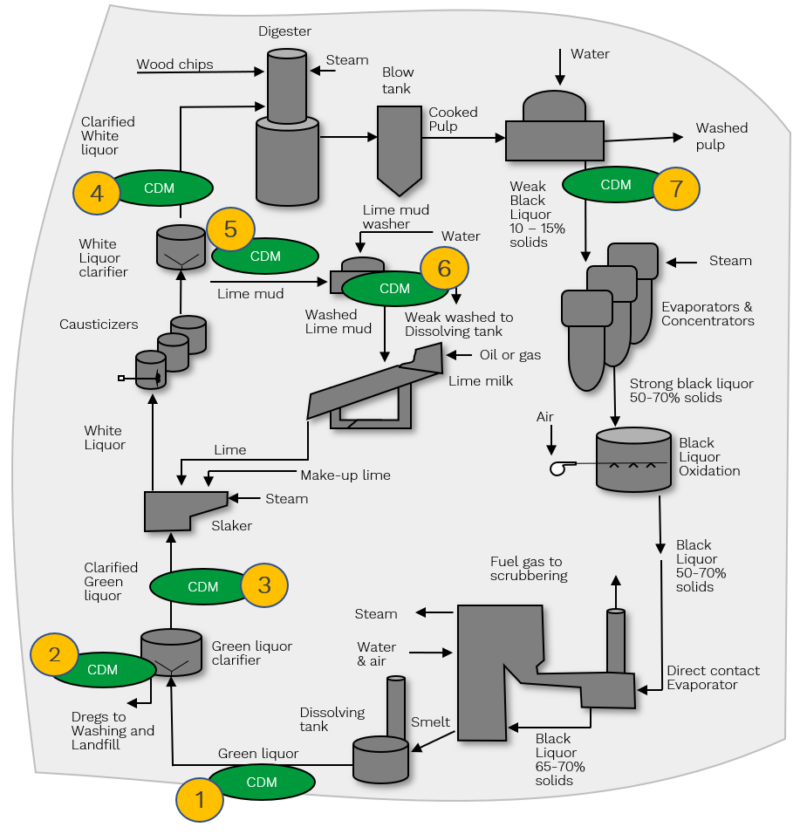

Tora zvinongedzo kubva padhayagiramu iri pamusoro mukugadzira mapepa, pane mapoinzi manomwe ekuisa kemikari density mita yekuita optimization yakazara. Ivo vanoshanda muzvikamu zvinotevera:

1. Kunyunguduka kwedoro dema mumvura;

2. Green doro density kana concentration yekutarisa;

3. White doro density kana kutarisisa kwekutarisa;

4. Lime slurry density kana kutarisa kwekutarisa;

5. Weak black liquor density kana concentration.

Iyo kraft process inoshandura huni kuita pulp yehuni, umo doro dema kana doro rinoshandiswa rinoumbwa nehuni pulp. Zvadaro doro dema rinogadziriswa kusvika doro regirini ragadzirwa. Uyezve, inogona kushandurwa kuita doro chena nekuwedzera lime mukaka kuti udzoke. Naizvozvo, density kana kudzora kwekutarisa mune kumusoro kuyera mapoinzi kwakakosha pamhando uye kudzora mutengo.

Inokurudzirwa Density Meter

Lonnmeterpulp density mitandiyo yakanakira sarudzo yekuenderera mberi density yekutarisa mukunyatso kutonga, ichipa kuverenga chaiko kune vanoshanda munguva chaiyo. Kuverenga kwayo chaiko kunogona kusvika ±0.002g/cm³, uye kuyerwa kwechiyero kunowira mu 0-2 g/cm³. Iyo inobuda inounzwa mune 4-20 mA chiratidzo. Kuti vashandisi vekupedzisira vagadzirise maparameter ekugadzirisa ipapo kuti awedzere kugadzikana mhando uye kuenderana, sekuwedzera kwepepa pulp, zvemukati zvemvura uye chiyero chekushushikana.

Uye zvakare, chaiyo-nguva yekutarisisa yepepa pulp inobatsira kuwana zvisizvo mukugadzirisa, senge kuchinjika kuchinjika, kusafanana kwepepa pulp uye kunyangwe kuputsika kwemidziyo. Ipapo mamwe matanho anogona kutorwa nekukasira kudzivirira kurasikirwa kwekugadzirwa uye zvisina basa byproducts.

Bata injinjini yedu kuti uwane rumwe ruzivo nezve pulp density mita, uye iwe unogona kuwana mazano ekutenderera nezve kusarudza yakakodzera inline density mita. Kumbira mutengo wemahara izvozvi!

Nguva yekutumira: Jan-06-2025