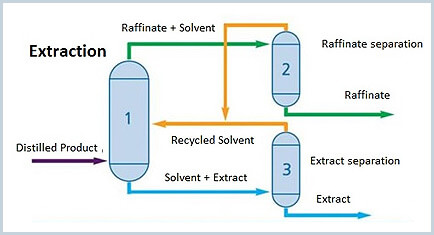

Mukuita kwakaomarara kuyerera kwekuzora mafuta solvent kunatsa, density control inomhanya mukati memaitiro ese emafuta ekuzora density kuyerwa. Nheyo yekubvisa inoshandiswa kupatsanura zvisina kunaka zvikamu kubva pakuzora mafuta zvikamu. Iyi nzira inoshandisa zvinonyungudutsa zvakaita sefurfural uye phenol kuwana mvura-chikamu kudhirowa pasi pemamiriro ekushisa chaiwo, kunyanya kubvisa polycyclic pfupi-side-chain hydrocarbons uye sulfur/nitrogen-ine makomisheni.

Iyo yakapfuma yekunyungudutsa chikamu ine isina-yakanakira zvikamu uye yakanyatso kucheneswa oiri chikamu chinopinda kupatsanurwa kwekutanga mukoramu yekubvisa, ichiyerera ichibuda kubva kwakasiyana zvitoro zvichiteerana. Iyo yakapfuma yekunyungudutsa chikamu inopinda iyo yakanyungudutsa yekudzoreredza sisitimu, uko iyo solvent inodzokororwa kuburikidza ne distillation nedzimwe nzira; chikamu chemafuta akacheneswa chinopinda maitiro anotevera akadai sekubvisa uye kuomesa kuti uwedzere kubvisa zvakasara zvinonyungudutsa, kuwana akakwenenzverwa akakwenenzverwa ekuzora mafuta ega ega.

Mhedzisiro yeDensity Measurement Errors

Zvakawanda Zvisaririra zveZvisina-Ideal Zvikamu

Kana iyo density control pane yakanatswa mafuta inobuda yakawandisa, izvo zvakasara zvezvisiri-zvakanakira zvikamu zvichapfuura mwero, zvakanyanya kuderedza kupikisa kweoxidation uye kugadzikana kwekupisa kwemafuta ekuzora. Izvi zvinozokonzera abnormal viscosity index, kutadza kuzadzisa zvinodiwa nemamiriro ekushanda, uye zvinogona kutotungamira kune ngura yemidziyo uye nyaya dzekuchengetedzwa kwezvakatipoteredza nekuda kwekusara kwesolvent.

Njodzi ye Solvent Residue

Kusaruramisa density control kunogona kukonzera kubviswa kusina kukwana kwezvinonyungudutsa (senge furfural) mumafuta akacheneswa. Zvisaririra zvinonyungudutsa zvinosvibisa zvinhu zvesimbi. Kunyanya muminda-yakanyanya-chaiyo senge oiri yekuzora nendege, inogona kukonzera njodzi dzakakomba dzekuchengetedza senge chisimbiso kuchembera uye kupera kwecorrosion.

Kakawanda Kukundikana muSolvent Recovery System

Abnormal density panzvimbo inonyungudutsa yakapfuma inotungamira mukudzikiswa kwechikamu, kunetesa simba rekunyungudutsa, uye kugadzira kutenderera kunotyisa. Kuunganidzwa kwemvura kuchakonzera solvent emulsification, inoda kumwe kurapwa. Kusachena kunopinda muhurongwa kunovharawo michina, kupfeka zvikamu, uye kuwedzera kuchengetedza uye kuderera kwemitengo.

Dambudziko muEconomic Benefits uye Kutevedzera

Kusarurama density control kuchawedzera mitengo yakadai sekugadzirisazve chigadzirwa, tsvina inonyungudutsa, uye kugadzirisa kwemidziyo, uye zvinogona kutungamira kune zvirango kana kunyange kumiswa kwekugadzira uye kugadzirisa nekuda kwekusatevedzera kwezvakatipoteredza.

Extraction Column / Solvent Recovery System

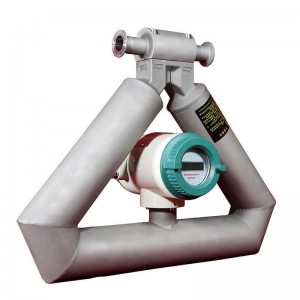

Mumafuta ekuzora anonyungudutsa ekunatsa maitiro, iyo yekubvisa mbiru uye solvent kudzoreredza sisitimu ndiyo yakakosha link. Iko kunyatso tarisisa uye kutonga kwe density ma parameters inobata zvakanangana nemhando yechigadzirwa, kugona kwekugadzira, uye kuchengetedzeka. Sechishandiso chenguva chaiyo chekutarisa, iyo inline density mita inogona kuwana inoshanduka optimization yemakiyi maitiro maparamita nekuenderera mberi nekuunganidza fluid density data uye kubatana neiyo control system. inline density metres anowanzo kuisirwa papombi yekubuda yeoiri yakacheneswa kumusoro kwekoramu uye pombi yekubuda kweiyo yakapfuma solvent pazasi kwekoramu.

Core Mabasa einline density metres

Dynamic Adjustment ye Solvent Ratio

Kana iyo density yemafuta akacheneswa kumusoro kwekoramu yakawandisa (ine zvimwe zvakasara zvisiri-zvakanakira zvikamu), iyo solvent jekiseni vhoriyamu inozowedzerwa otomatiki kuvandudza kudhirowa kushanda; kana density yakanyanya kuderera (ine yakawandisa solvent), kushandiswa kwesolvent kunoderedzwa kudzivirira tsvina.

Yambiro Yepakutanga yePase Separation Abnormalities

Kana "mafashamo" kana "channel" ikaitika mukoramu yekubvisa, iyo densitometer data inoshanduka zvine chisimba, uye sisitimu inogona kuburitsa maaramu panguva uye kugadzirisa ma parameter ekushanda (seyekuyerera uye tembiricha) kudzivirira tsaona dzekugadzira.

Optimization of Extraction Column Load

Nekuenderera mberi nekutarisa density data, kuyerera kwezvinhu mukoramu kwakaringana kudzivirira kuwandisa kwenzvimbo kunokonzerwa nekusaenzana kwehuwandu uye kuwedzera kutenderera kwekushandisa kwemidziyo.

Zvakanakira zveLonnmeter Inline Density Meters

Lonnmeterinline density metresvakamira pakati pezvigadzirwa muindasitiri imwe chete nekuita kwavo kwakasimba uye kuchinjika kwakanakisa mushure memakumi emakore ekusimbiswa kwemusika, zvichipa mhinduro dzakavimbika dzekutarisa kwemvura muindasitiri dzakasiyana. Vatengi vanogona kusarudza inline density metres nekurongeka kwakasiyana zvichienderana nemamiriro ekushanda.

Panyaya yekurongeka, Lonnmeter inline density metres yasvika padanho repamusoro muindastiri, nemamwe mamodheru achiwana huchokwadi hwe ± 0.0005 g/cm³, ichipfuura avhareji nhanho yezvigadzirwa zvakafanana. Vatengi vanogona kuchinjika kusarudza zvigadzirwa zvine mwero wakasiyana zvichienderana nemamiriro ekushanda, kubva kune yakakosha ± 0.01 g/cm³ kusvika kune yepamusoro-chaiyo ± 0.0005 g/cm³, kuwana chiyero chepamusoro pakati pemutengo nekuita.

Kune midhiya inoparadza, Lonnmeter inopa zvinhu zvakasiyana-siyana zvisingadziviriri, zvinosanganisira Hastelloy, titanium alloy, uye polytetrafluoroethylene, iyo inogona kumira kwenguva refu kukukurwa kweiyo yakasimba corrosive media senge hydrochloric acid uye sulfuric acid, ichiwedzera zvakanyanya hupenyu hwesevhisi yemidziyo uye kuderedza mari yekugadzirisa.

Lonnmeter inline density metres inotsigira nzira dzakawanda dzekuisa, kusanganisira dzakaiswa padivi, dzakaiswa pamusoro, uye pombi-yakaiswa, iyo inogona kunyatsoenderana nekumisikidzwa kweakasiyana michina uye mapaipi. Panguva imwecheteyo, ivo vakashongedzerwa neakapfuma data data senge 4-20mA, RS485, uye Modbus, iyo inogona kubatanidzwa zvisina musono kumasisitimu ekutonga akadai seDCS nePLC kuti iwane kutarisisa kure uye otomatiki kutonga, kubatsira mabhizinesi kuvandudza hunyanzvi hwekugadzira uye hungwaru mazinga.

Mumunda wekuzora mafuta ekubvisa, chaiyo density yekutarisa ndiyo kiyi yekuvandudza chigadzirwa chemhando uye kugona kugadzira. Lonnmeter inline density metres yakabatsira mabhizinesi mazhinji kuwana kugadzirwa kwakanaka nezvakawanda zvakanakira.

Kana iwe zvakare uchitsvaga yakavimbika density kuyerwa mhinduro, unogamuchirwa kutora danho izvozvi! Dzvanya kuti utange kubvunza kuti utore yemahara yakadzama chigadzirwa katalog yeLonnmeter inline density metres, inovhara iyo yakazara huwandu hwechigadzirwa parameter nekurongeka kwakasiyana uye zvinhu zvekukubatsira nekukurumidza kusarudza iyo chaiyo modhi; iwe unogona zvakare kuvhura akapfuma makesi evatengi muindasitiri yekuzora mafuta ekuzora kuti unzwisise zvakadzama magadzirisiro atinoita matambudziko ekutarisa density kumabhizinesi uye kuwana kuderedzwa kwemitengo uye kuvandudza hunyanzvi.

Nguva yekutumira: Jun-05-2025