Muna 1938, Nestle yakagamuchira kuomeswa kwepamberi kwekugadzira kofi, ichibvumira hupfu hwekofi yekukurumidza kunyungudika mumvura inopisa. Mukuwedzera, vhoriyamu diki uye saizi inoita kuti zvive nyore mukuchengetedza. Saka yakakurumidza kukura mumusika mukuru. Parizvino mhando dzekofi dzakakurumbira dzinosanganisira Nestle, Maxwell, UCC, nezvimwe.

Instant coffee production process

Instant kofi chinwiwa chekofi chakasimba chinogadzirwa nekofi bhinzi yakagochwa nekupwanya, inonyungudika inotorwa nemvura, uye yobva yaomesa nemhepo inopisa kana kuomesa nechando. Zviri nyore kunyungudutswa mumvura uye wodzokera kumvura yekofi ine yepakutanga kuravira uye kunaka. Maitiro ekugadzira ndeaya anotevera: kuongororwa kwebhinzi yekofi, kubviswa kwehutsvina, kugocha, kugaya, kuburitsa, kuisa pfungwa, kuomesa, kurongedza.

II. Mapoinzi Akakosha eInstant Coffee Production process

(I) Pre-Kurapwa kweRaw Coffee Beans

Kutanga, zvinhu zvakasvibirira zvinofanira kunyatsosarudzwa. Benzi dzekofi itsva dzakapenya, dzakatenderera uye dzakafanana muhukuru, kusanganisa kuvhuvhu, yakaviriswa, nhema, inodyiwa nehonye, yakatyoka zvakanyanya uye dzimwe bhinzi dzakaderera, pamwe nekusachena kwakasiyana semateko embeu, mabhuroko evhu, matanda, matombo, nesimbi. Kuti uve nechokwadi chemhando, kupatsanurwa kunogona kuitwa nenzira yevibrating skrini, kudzvinyirirwa kwemhepo kana vacuum kufambisa.

(II) Kugocha

Kugocha ndiyo yakasarudzika nzira yekuumbwa kwekunaka uye kunaka kwekofi yekukurumidza. Kutengeserana kwebhinzi dzekofi kunotora hafu inopisa-mhepo yakananga moto roaster kana inopisa air roaster ine makamuri ekugocha muchimiro chedhiramu inotenderera kazhinji. Tembiricha yekugocha uye nguva yekugocha ndizvo zvakakosha zvinosarudza zvinhu.

Kureba kwenguva yekugocha kunosiyana kwete nekuda kwekusiyana uye rudzi rwekofi, asiwo zvinoenderana nehuwandu hwekugocha hunodiwa kune chigadzirwa chekupedzisira. Nguva pfupi yekugocha inoratidza kuti bhinzi yekofi yakapfava ine acidity yakasimba, kuvava kusina simba uye kudhirowa nyore mushure mekukuya. Kusiyana neizvi, nguva yakareba yekugocha inoratidza bhinzi yekofi ine crispy ine acidity isina kusimba, kuvava kwakasimba uye kushomeka-kushanda mukubvisa kune yakawanda yakatsetseka poda.

Kusakwana kugocha kuchaguma nekunhuhwirira kwakashata, ruvara rwakashata rwechigadzirwa chakapedzwa uye chiyero chakaderera chekubvisa; kugocha zvakanyanya kunokonzeresa kunaya kwemafuta akawanda, izvo zvinotadzisa kutorwa uye kukanganisa basa rekupfapfaidza kuomesa. Naizvozvo, mamiriro akanaka ekugocha anofanirwa kutariswa nerudzi rwechigadzirwa, kunhuhwirira, goho, kugona kwehupfumi uye kugadzirwa kwemidziyo yekugadzira mamiriro.

Kana bhinzi dzekofi dzasvika padanho rinodiwa rekugocha, dzima moto, rega kudziyisa, uye tonhoresa bhinzi dzekofi nekukurumidza. Nokuti kunyange kana kupisa kwakamira, kupisa mukati mebhinzi dzekofi kucharamba kuchigochwa kwenguva yakati, saka mushure mokunge bhinzi dzekofi dzadururwa kunze kwedhiramu rekugocha, feni yekupisa inofanira kubatidzwa kuti itonhodze kumisa tembiricha kuti isakwira. Muindasitiri, imwe mvura inotonhora inopfapfaidzwa mukamuri yekugocha kuti itonhodze, uye ipapo bhinzi yekofi yakakangwa inoburitswa kubva mukamuri yekugocha kuti itonhodze.

(III) Static Storage

Zvakanakisisa kuchengeta bhinzi yekofi yakakangwa kwezuva rimwe chete kuitira kuti carbon dioxide nemamwe magasi awedzere kunyungudika uye asununguke, uyewo achinyatsotora mwando uri mumhepo kuti apfave bhinzi, izvo zvinoita kuti pave nekudzurwa. Saizi yekukuya particle size inoenderana nemidziyo yekubvisa inoshandiswa. Fine particles zvinokonzeresa kudhirowa kwepamusoro-soro asi zvinotadzisa kufefeta kunotevera nepo zvimedu zvakakoshwa zvakaoma kubviswa asi zviri nyore kusefa. Kazhinji, avhareji yedhayamita yepasi kofi zvimedu zvinenge 1.5 mm.

(IV) Kubvisa

Kubvisa ndiyo yakanyanya kuoma yepakati chikamu chekukurumidza kugadzirwa kwekofi. Mudziyo unowanzo shandiswa pakuchera unonzi mudonzvo, unosanganisira matangi matanhatu kusvika masere akabatana nemapombi uye anogona kugadzirwa achichinjana kuita unit inoshanda.

(V) Kuparadzana kwakasimba-kwakasimba

Iyo mvura yekofi yakabviswa ichava nemafuta akawanda akasara. Izvi zvinoda kuparadzaniswa kwemvura-yakasimba yemvura yekofi isati yaendeswa kune imwe nzira inotevera. A butterfly separator anogona kuwana chinodiwa kupatsanura mhedzisiro mune zvakajairika.

(VI) Kuisa pfungwa

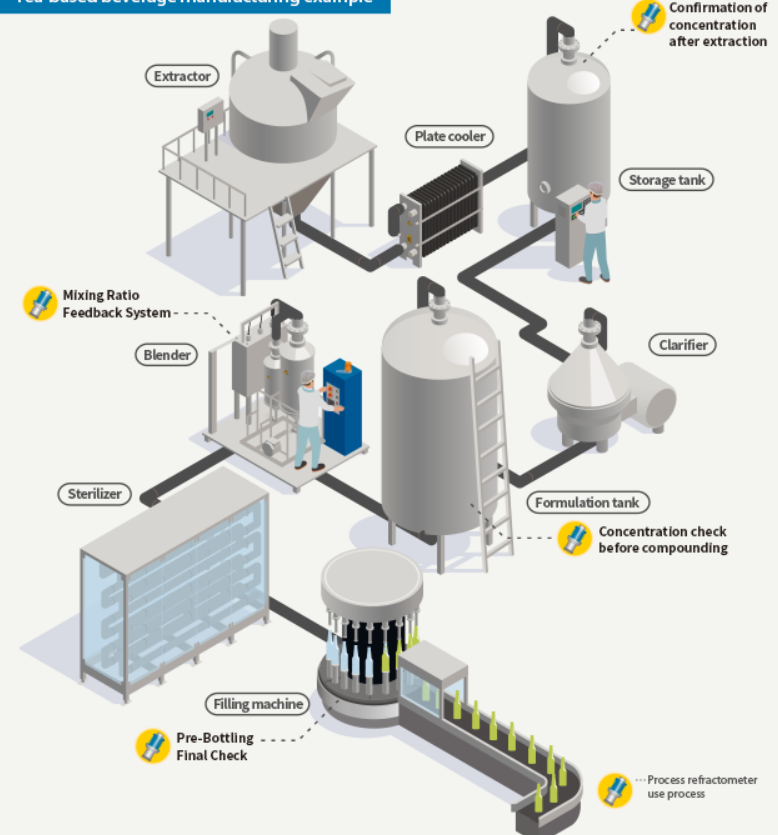

Concentration yakakamurwa kuva vacuum concentration, centrifugal concentration uye chando chakazara. Kuti uvandudze kuomesa zvakanaka, kuderedza kushandiswa kwemidziyo uye kushandiswa kwesimba, iyo yakasimba yekumisikidza inoderedzwa kusvika kupfuura 35%. Vacuum concentration inodzikisira panovira mvura kusvika pa60 degrees muvacuum pressure pamusoro pe0.08Mpa. Kuitira kuti mvura yacho iwedzere kukurumidza. An inline coffeuye slurry concentrationmitainobatsira kupedzisa-kushandisa kunze kwekudzokororwa uye kunetsa kutsunga kwekutarisa neiyo yepamusoro-yechokwadi yekutarisa munguva chaiyo. Iko kusungirirwa kweiyo concentrate kazhinji haipfuure 60% (refractometer). Sezvo tembiricha yemvura yakanyungudutswa inobuda mushongwe inopfungaira yakakwira kupfuura tembiricha yekamuri, inofanira kutonhodzwa isati yatumirwa kutangi rekuchengetedza kuderedza kurasikirwa.

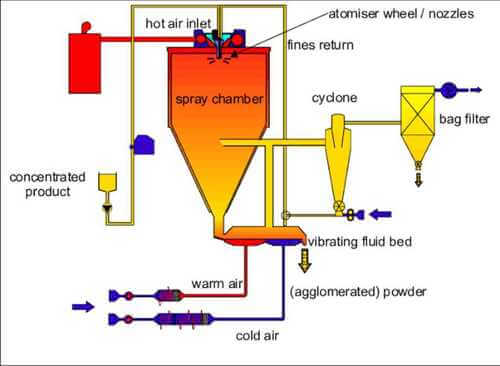

(VII) Kupfapfaidza Kuomesa

Mvura yakanyungudutswa inotakurwa zvakananga kumusoro kweshongwe yekuomesa yekupfapfaidza kuburikidza nepombi yekumanikidza, yakapfapfaidzwa mumhute nepfuti yekupfapfaidza yekumanikidza, uye yakaomeswa kuita upfu mukupisa uye mhepo inoyerera inosvika 250 ° C. Vacuum kuomesa kana kuomesa tekinoroji inogona kushandiswawo kuomesa. Kuomesa kuomesa tekinoroji ndeyekuomesa iyo yekofi inonamira pakudziya kwakadzika, uye mvura iri mairi inoomeswa kuita zvidimbu zveaizi echando, uye yozopisa uye kunyungudutswa pasi peyakanyanya vacuum mamiriro kuti azadzise chinangwa chekudzika-tembiricha kuomesa. Mushure mekunge iyo concentrate yagadziriswa, iyo inodiwa yekuwedzera kurapwa inogona kuitwa pane yekutarisa, uye inogona zvakare kuvandudzwa kuita chinwiwa chemvura.

Dzvanya pano kuti uwane zvimwemhinduro dze inline concentration yekutarisa. Kana kuti unogona kubataLonnmeterzvakananga nezvaunoda chaizvo.

Nguva yekutumira: Feb-10-2025